The switchgear industry, long regarded as the backbone of electrical power distribution and protection, is undergoing a significant transformation driven by automation. As power systems become more complex and the demand for reliable, safe, and efficient electricity grows across industries, automation has emerged as a critical enabler across the entire switchgear value chain—from design and manufacturing to testing, operation, and maintenance. With the advent of smart factories, digital substations, and Industry 4.0 frameworks, automation is reshaping not only how switchgear is produced but also how it performs in increasingly dynamic power networks.

Automation in Switchgear Manufacturing

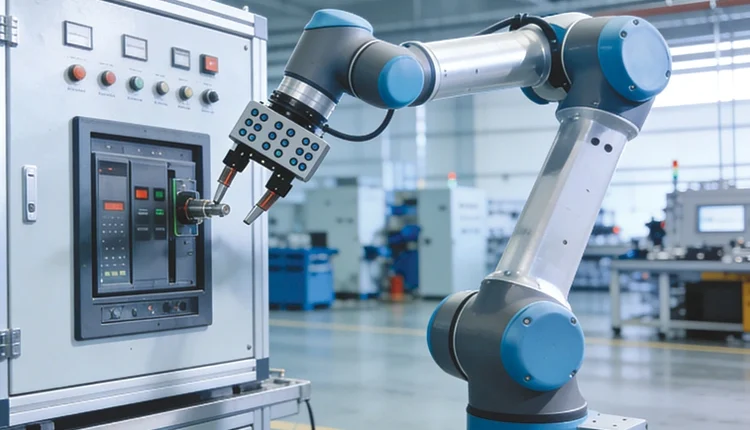

Historically, switchgear manufacturing relied heavily on manual processes, particularly in fabrication, assembly, wiring, and inspection. While effective in the past, these methods are increasingly challenged by rising expectations around quality, safety, delivery timelines, and compliance with global standards. Automation has addressed these challenges through CNC-driven sheet metal processing, robotic welding, automated busbar fabrication, and conveyorised powder coating lines. These technologies ensure precision, repeatability, and scalability, enabling manufacturers to meet growing domestic and export demand with consistent quality.

Streamlining Assembly and Material Handling

Automation has had a particularly strong impact on assembly operations, especially in the low-voltage (LV) and medium-voltage (MV) switchgear segments, where production volumes are high and configurations vary widely. Automated and semi-automated assembly stations, robotic fastening systems, and pre-engineered wiring harnesses reduce human error while improving productivity. Automated guided vehicles and intelligent material handling systems further enhance shop-floor efficiency and safety, supporting modular manufacturing approaches that are increasingly preferred in LV and MV switchgear production.

Automated Testing and Quality Assurance

Testing is a critical stage in switchgear manufacturing, as even minor inconsistencies can compromise safety and reliability. Automated testing systems now perform routine and type tests such as insulation resistance checks, high-voltage withstand tests, functional verification, and protection relay testing. This is especially beneficial in MV switchgear, where insulation integrity, contact alignment, and protection coordination are paramount. Digitally captured test data ensures traceability, faster approvals, and compliance with IEC, IEEE, and IS standards, while also supporting continuous quality improvement.

Emergence of Smart and Intelligent Switchgear

Automation today extends beyond the factory floor into the switchgear itself. Modern LV and MV switchgear is increasingly equipped with sensors, intelligent electronic devices, and communication modules that enable real-time monitoring of electrical and environmental parameters. Integrated with SCADA systems, energy management platforms, or cloud-based dashboards, intelligent switchgear provides enhanced visibility into system performance and supports faster, data-driven decision-making.

Predictive Maintenance and Asset Optimisation

The combination of automated switchgear and digital analytics has enabled a shift from time-based to condition-based maintenance strategies. Continuous monitoring of parameters such as temperature rise, partial discharge, and contact wear allows early detection of abnormalities. This approach is particularly valuable in MV installations serving utilities, renewable energy plants, metros, and critical industrial facilities, where unplanned downtime can have significant operational and financial consequences.

Role of Automation in Digital Substations and Smart Grids

In digital substations and smart grid environments, automated switchgear functions as a connected node within a larger, intelligent ecosystem. Seamless communication between LV and MV switchgear, protection relays, transformers, and control systems enables rapid fault detection, isolation, and system restoration. As renewable energy integration, electric vehicle infrastructure, and distributed generation increase grid complexity, automation becomes essential for maintaining stability and reliability.

Enhancing Safety through Automated Systems

Safety remains a top priority across all switchgear segments, and automation has significantly reduced risk to personnel. Automated interlocks, remote operation, and real-time condition monitoring limit the need for manual intervention near live equipment. Advanced arc fault detection and mitigation systems, integrated with automated controls, enhance protection in LV and MV installations, particularly in industrial plants, substations, and confined electrical rooms.

Business and Competitiveness Advantages

From a commercial standpoint, automation offers switchgear manufacturers a decisive advantage, especially in high-volume LV and MV segments. Automated production lines enable shorter lead times, consistent quality, and greater flexibility in handling customised configurations. This supports mass customisation and strengthens competitiveness in both domestic and global markets, where cost efficiency and reliability are key differentiators.

Automation and Workforce Transformation

Rather than displacing manpower, automation is reshaping roles within the switchgear industry. The focus is shifting from manual assembly to higher-value activities such as system integration, programming, testing, diagnostics, and data analysis. This transition aligns well with modern manufacturing practices and supports long-term skill development within the industry.

Challenges and the Way Forward

Despite its clear benefits, automation adoption involves challenges including capital investment, integration complexity, and cybersecurity considerations. These challenges are more pronounced for smaller manufacturers, though modular automation solutions and scalable digital platforms are making adoption more accessible. While high-voltage (HV) switchgear typically involves lower volumes and project-specific designs—limiting full-scale automation—selective automation in precision manufacturing, testing, and digital monitoring continues to add value.

Conclusion

Automation has emerged as a defining force in the switchgear industry, with LV and MV segments benefiting the most due to their volume, complexity, and growing digital integration. By enhancing manufacturing efficiency, operational reliability, safety, and lifecycle performance, automation is enabling switchgear to evolve from a passive protective component into an intelligent asset within modern power systems. As energy infrastructure becomes smarter and more distributed, automation will remain central to the industry’s future growth and competitiveness.