Imasieves™ Static Dissipative Sifter Sieves: Engineering Safety & Efficiency in Industrial Screening

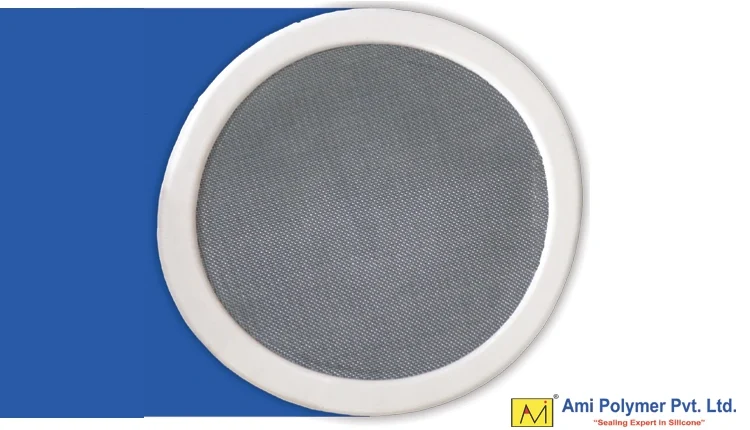

Introduction: Ami Polymer Pvt. Ltd Static Dissipative Sifter Sieves

Ami Polymer Pvt. Ltd. has long been recognized as a pioneer in high-performance polymer and silicone engineering solutions. With a focus on quality, innovation, and industrial safety, the company has consistently delivered products that address real world challenges in pharmaceutical, chemical, food, and materials processing industries.

Among its cutting-edge offerings, static dissipative sifter sieves exemplify Ami Polymer’s commitment to precision engineering and operator safety. These sieves combine material science expertise, advanced manufacturing techniques, and safety-conscious design, making them indispensable in modern industrial screening processes.

The Challenge of Static Electricity in Screening

The food and pharmaceutical industries are facing many challenges regarding safe processing operations. Dynamic mechanical movements inherent in drug manufacturing and delivery systems generate static electricity on component surfaces. Silicone, widely used in pharma for fluid delivery and sealing, naturally has insulating properties, which allow static charges to develop on its surface. When these charges come into contact with flammable processing solvents, the risk of fire incidents increases significantly. Recent years have seen multiple fire events linked to static electricity in these sectors.

Industrial sieving operations often involve fine powders, granules, and dry materials, which can generate static electricity during handling. If uncontrolled, this static can lead to:

- Material adhesion to sieve surfaces

- Inaccurate particle separation

- Reduced throughput and frequent cleaning

- Equipment damage

- Fire or explosion hazards in extreme cases

Material Conductivity and Static Charge Dissipation

Materials used in sieves can be categorized based on their electrical conductivity as follows:

Increasing conductivity corresponds to better capability to dissipate static charge safely.

| Conductivity Range (Ohm-Ω) | Category |

| 10³ to 10⁵ | Conductive |

| 10⁶ to 10⁹ | Dissipative |

| 10¹⁰ to 10¹¹ | Anti-Static |

| >10¹² | Insulative |

Ami Polymer’s static dissipative sieves are engineered specifically to fall within the dissipative range, allowing them to gradually discharge static electricity while maintaining screening integrity.

Engineering and Design Features of Ami Polymer’s Static Dissipative Sieves

Our static dissipative sieves are technologically advanced yet elegantly simple in application. Key design highlights include:

- Silicone surfaces that are completely smooth and crevice-free, preserving integrity and hygiene critical in pharmaceutical and food applications.

- The entire sieve acts as an electrostatic dissipater, eliminating fire, explosion, and electrocution hazards.

- The sieves are successfully tested to meet FDA 21 CFR 177.2600 food grade standards.

Principle of Static Dissipative Sieves

Static dissipative sieves operate on controlled electrical conductivity, which allows them to slowly release static charges through grounding systems. Unlike fully conductive materials, which discharge rapidly, or insulative materials that trap charges, these sieves strike a balance dissipating charges safely without sudden sparks.

Materials used include specially treated metals, conductive coatings, or polymer composites embedded with carbon or conductive fibers. This engineering ensures both safety and product quality, even under high-speed or low-humidity conditions.

Advantages of Static Dissipative Sifter Sieves

- Enhanced Safety: Reduces risks of sparks, fires, and explosions in hazardous environments.

- Consistent Screening Accuracy: Prevents material sticking, ensuring uniform particle size distribution.

- Increased Productivity: Less clogging and downtime lead to higher throughput.

- Extended Equipment Life: Reduces static-related wear on meshes and frames.

- Superior Product Quality: Uniform separation improves batch consistency and reduces contamination.

Industrial Applications

Static dissipative sieves by Ami Polymer are widely used in:

- Pharmaceuticals: APIs, excipients, granulation powders

- Food & Beverages: Flour, sugar, spices, additives

- Chemicals: Pigments, resins, specialty powders

- Plastics & Polymers: Resin powders, master batches

- Electronics & Batteries: Fine, static-sensitive materials

These sieves are often mandatory for regulatory compliance in dust-sensitive or explosive environments.

Maintenance and Operational Considerations

| Feature | Benefit |

| Crevice-Free cGMP Quality | Ensures easy cleaning & hygiene |

| Optimum Porosity for High Throughput | Maximizes processing efficiency |

| Traceability to International Standards | Maintains quality assurance |

| Precise & Controlled Aperture Sizes | Ensures consistent particle sizing |

| Durability | Long service life |

| TSE & BSE Free | Safety compliance |

Optimal performance requires:

- Proper grounding during installation

- Regular inspection for coating wear or damage

- Non-abrasive cleaning methods

- Electrical resistance verification

Failure to maintain grounding continuity can reduce static dissipation efficiency and compromise safety.

Future Trends

Growing safety and efficiency demands drive innovation in static dissipative sieves, including:

- More durable anti-static coatings

- Improved conductivity control

- Integration with smart monitoring systems for predictive maintenance

Ami Polymer continues to lead in developing these advanced screening solutions.

Conclusion

Static dissipative sifter sieves from Ami Polymer Pvt. Ltd. represent a vital engineering solution addressing static electricity hazards in industrial screening. By improving safety, efficiency, and product quality, they have become indispensable in industries handling fine and sensitive materials reflecting Ami Polymer’s commitment to innovation, safety, and excellence.