Ensuring Hygiene, Safety and Reliable Performance in Food Processing Applications

The food and beverage industry operates under strict hygiene, safety, and quality regulations. From raw material intake to final packaging, every component used in food processing must comply with food safety standards. Among these components, food-grade hoses play a vital role in ensuring contamination-free transfer of liquids, powders, and granules.

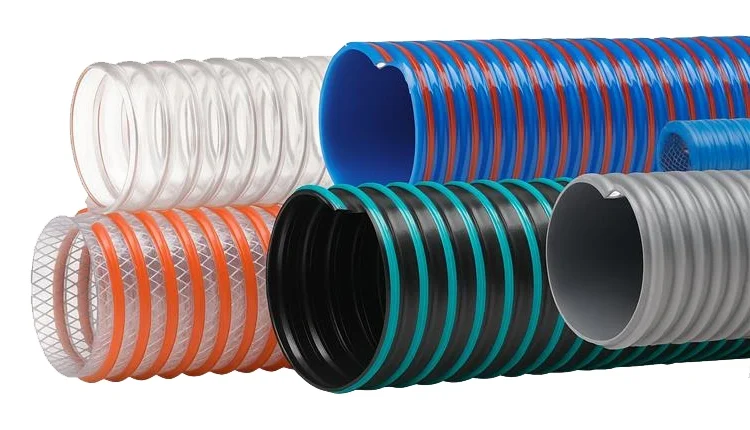

PU and PVC food-grade hoses are widely adopted across the industry due to their superior performance, durability, and regulatory compliance. Designed specifically for hygienic applications, these hoses help manufacturers maintain product integrity while improving operational efficiency and safety.

Importance of Food-Grade Hoses in Food Safety

Using non-food-grade hoses can result in serious risks such as microbial growth, chemical leaching, taste or odor contamination, and product recalls. Poor hose quality may also lead to production downtime, equipment damage, and failure to meet regulatory requirements.

Food-grade PU and PVC hoses are manufactured with smooth inner surfaces that prevent residue build-up and support effective CIP operations. Their hygienic construction ensures safe handling of consumable products while maintaining compliance with international food safety standards.

PU and PVC Hoses – Material Characteristics

PU Food-Grade Hoses

PU hoses are known for their exceptional flexibility, excellent abrasion resistance, and wide temperature tolerance. These properties make them ideal for handling powders, granules, and abrasive food materials such as flour, sugar, grains, and spices. PU hoses perform reliably in demanding applications where durability and long service life are essential.

PVC Food-Grade Hoses

PVC food-grade hoses offer excellent transparency, good chemical resistance, and cost-effectiveness. Their clear construction allows visual monitoring of product flow, which is especially important in beverage, dairy, and liquid food applications. PVC hoses are widely used where moderate flexibility and pressure handling are required.

Both PU and PVC hoses are engineered to deliver consistent performance, hygiene, and durability across a wide range of food processing environments.

Technical Specifications – PU / PVC Food-Grade Hoses

| Parameter | PU Food-Grade Hose | PVC Food-Grade Hose |

| Material | Thermoplastic Polyurethane (TPU) | Polyvinyl Chloride (PVC) |

| Temperature Range | -40°C to +90°C | -10°C to +60°C |

| Flexibility | Excellent | Moderate |

| Abrasion Resistance | Excellent | Moderate |

| Transparency | Semi-transparent | Fully transparent |

| Working Pressure | Medium to High | Good |

| Vacuum Capability | Good | Moderate |

Technical Specifications – Application Wise

• Powder & Granule Transfer – PU Hose

• Flour, Sugar, Spices, Milk & Dairy Fluids – PU / PVC Hose

• Beer, Juices, Syrups – PVC Hose

•Bakery / Confectionery – PVC Hose

Application – Recommended Hose Type

• Powder & Granule Transfer – PU Hose

• Flour, Sugar, Spices – PU Hose

• Milk & Dairy Fluids – PVC Hose

• Beer, Juices, Syrups – PVC Hose

• Bakery / Confectionery – PVC Hose

• CIP / Utility Lines – PVC Hose

Applications Across the Food & Beverage Industry

PU and PVC food-grade hoses are extensively used across various food processing applications, including:

• Beverage Processing: Transfer of water, juices, syrups, and soft drinks

• Dairy Industry: Milk, cream, and dairy fluid handling

• Dry Food Handling: Flour, sugar, grains, and spices

• Bakery & Confectionery: Syrups, batters, and semi-solid food materials

• CIP & Utility Lines: Cleaning and sanitation systems requiring chemical compatibility

Their versatility makes them essential components in modern food processing facilities.

Compatibility and Hygiene Assurance

Good chemical compatibility is essential for CIP (Cleaning-In-Place) systems to ensure hygiene, safety, and long service life. Ami Polymer hoses are designed to withstand cleaning agents, oils, fats, and food-grade chemicals, reducing contamination risks and maintaining process integrity.

Why Choose Ami Polymer Hoses for the Food & Beverage Industry

Ami Polymer focuses on delivering hose solutions that meet FDA, EU, and other international food safety standards. Key advantages include:

• Food-grade compliant materials

• Smooth inner bore for enhanced hygiene

• Excellent flexibility and durability

• Abrasion and chemical resistance

• Transparent design for visual flow monitoring

• Reliable performance across wide temperature ranges

These features help food manufacturers maintain safety, efficiency, and regulatory compliance.

Conclusion

Selecting the right food-grade hose is essential for ensuring safe, efficient, and compliant food processing operations. PU and PVC hoses offer dependable solutions for a wide range of food and beverage applications. With premium materials, advanced manufacturing, and strict quality control, Ami Polymer continues to support the industry with hoses that deliver trusted quality, safety, and long-term value.